First characterization method for the morphology of slags successfully evaluated

AS PART OF THE GREEN ZINC PROJECT, INITIAL INVESTIGATIONS IN THE FIELD OF SLAG OPTIMIZATION FROM THE LEAD INDUSTRY SUCCEEDED IN DIFFERENTIATING BETWEEN CRYSTALLINE AND AMORPHOUS PARTS OF THE SLAG MORPHOLOGY. BASED ON THIS, A MORE COMPREHENSIVE EVALUATION OF THE MODIFIED SLAGS CAN NOW BE CARRIED OUT AND THUS A MORE TARGETED ZERO-WASTE CONCEPT CAN BE DEVELOPED FOR THE PROCESS UNDER CONSIDERATION.

Slags from Nonferrous Metallurgy are often a waste product. One aim of this project, in addition to CO2 neutrality, is to enable zero-waste concepts for the processes under consideration and thus to utilize the slags as by-products. For this purpose, the slag must be optimized, i.e. modified – by reduction, addition of additives and different cooling procedures – so that it can subsequently be used in the construction industry.

However, the characterization of corresponding, optimized by-products represents a decisive challenge, as a simple element analysis does not provide sufficient information about the possible use as a secondary raw material. Precise knowledge of the morphology and phases as well as grain shape and size is therefore essential for the assessment of suitable utilization strategies.

First successes were achieved by using transmitted light microscopy to determine the morphology of the slag produced more precisely. Crystalline and amorphous areas are clearly visible within the samples examined. In the corresponding laboratory-scale experiment, slag from the lead industry was reduced with petroleum coke, modified with Al2O3 and then further modified using different cooling methods. Approximately 0.5 kg of slag was poured once into a crucible at room temperature (air-cooled sample) and once into a water bath (water-cooled sample).

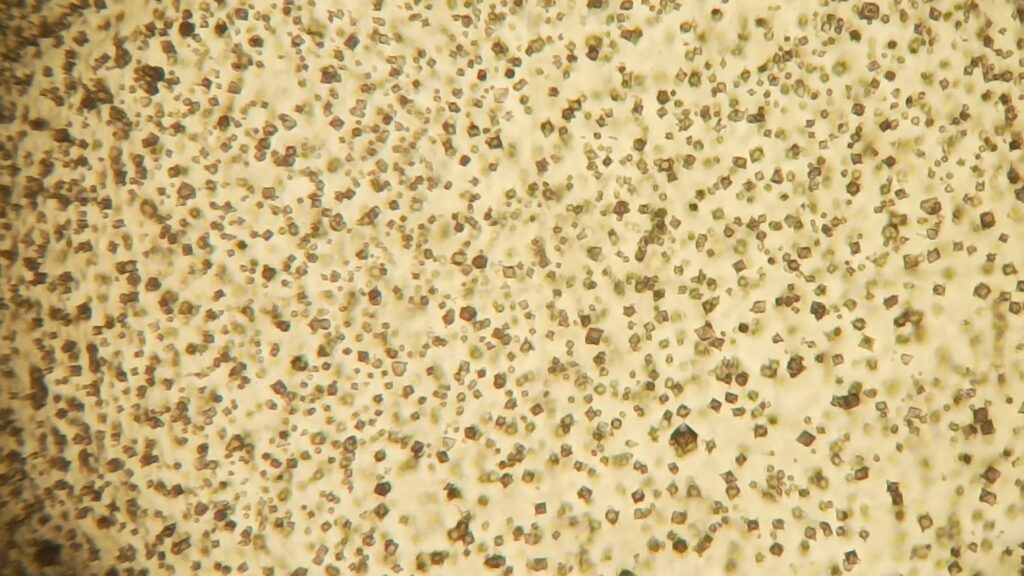

Microstructure of slag from the lead industry reduced with petroleum coke and modified with Al2O3, which was cooled in a crucible at room temperature (air-cooled sample)

Microstructure of slag from the lead industry reduced with petroleum coke and modified with Al2O3, which was cooled in a water bath (water-cooled sample)

Even in the short time window between the two cooling variants, there were clear differences. The air-cooled sample shows significantly more crystalline phases than the water-cooled sample. In the water-cooled sample, on the other hand, the formation of crystals is barely recognizable; here the amorphous portion predominates. In the transmitted light microscope, this can already be seen on a 10 µm scale.

Impacts and effects

Due to ever stricter environmental protection laws and the associated rising costs for landfills, it is becoming increasingly attractive for companies to establish zero-waste processes and thus avoid landfills. By recycling the slag, not only can the costs of landfill be avoided, but serious environmental pollution can also be prevented in the future. In addition, the reprocessing and remediation of existing landfills can be seen as a significant additional source of value creation.